The screen for the front cowl was clear and shiny when the motorcycle was new.

Whether it is a lightweight component for racing or a thick and sturdy genuine part, you may notice minor scratches that stand out and bother you. Since most screens are made of acrylic resin, good polishing with the right tips and tricks can erase scratches and restore the screen’s beauty. Let’s take a peek at some professional screen polishing tips and techniques.

- The next thing you know, it’s matted like frosted glass.

- Start with the base.

- Deciding to go for it, he started with scratch removal.Gradually increasing the grain size number.

The next thing you know, it’s matted like frosted glass.

This screen is a factory-smoked screen for the Suzuki GSX250S Katana that mounts over the headlight cowl. Whether clear or smoked, most of the manufacturer’s factory screens are made of acrylic resin material, which is often heat-molded. If they are made of acrylic, it seems to be relatively easy to remove scratches and polish them, but power tools are essential for the final finish polishing.

Start with the base.

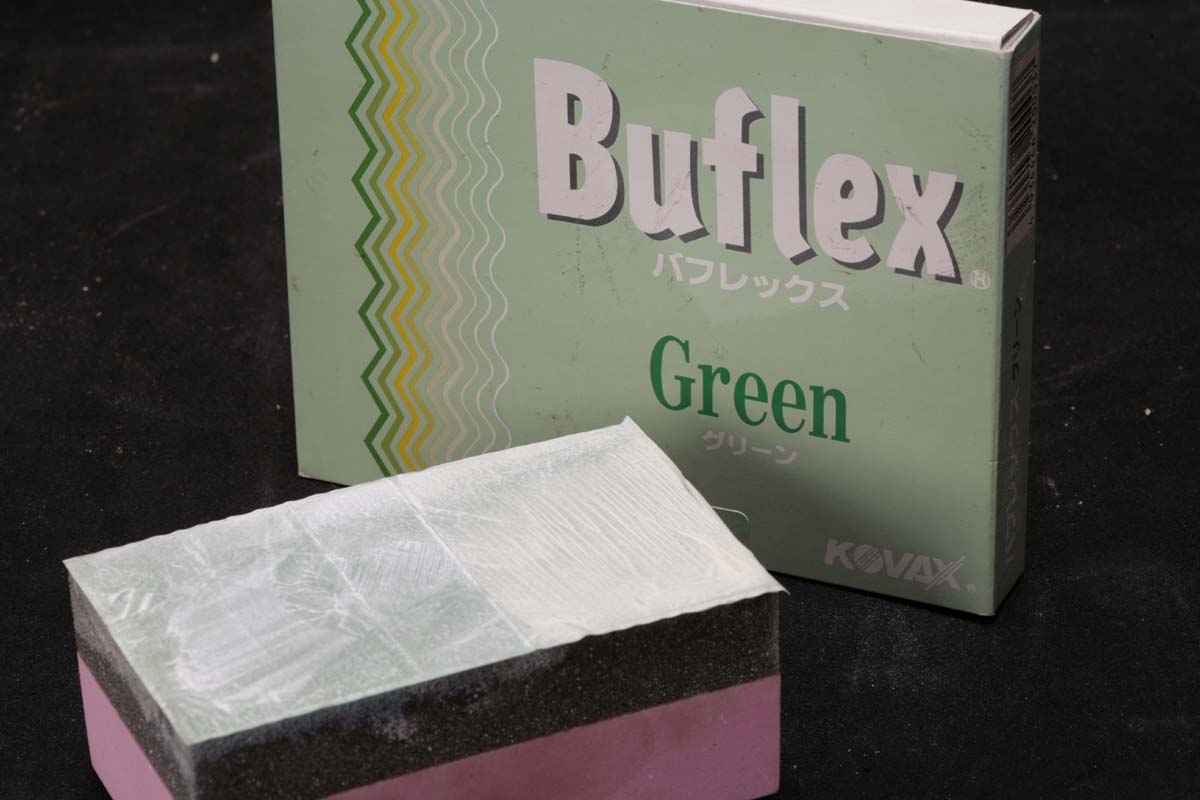

The grain size of water-resistant sandpaper should be used according to the depth of the scratches. If the scratches are not very deep, you should be able to remove the scratches by starting with 400-480 grade waterproof paper, and then gradually and thoroughly polishing from 600 to 800 to 1000 to 1200 to 1500 to 1800 to 2000 grade. When sharpening with this water-resistant paper, be careful to set the paper on a sponge block for stable application and to effectively use a spray mist to wash off any resin powder that has been removed while polishing. This is because if the scraped resin powder is rolled in, it will create new scratches in the resin powder. Finally, the professional polisher finishes with an abrasive called BUFFLEX GREEN.

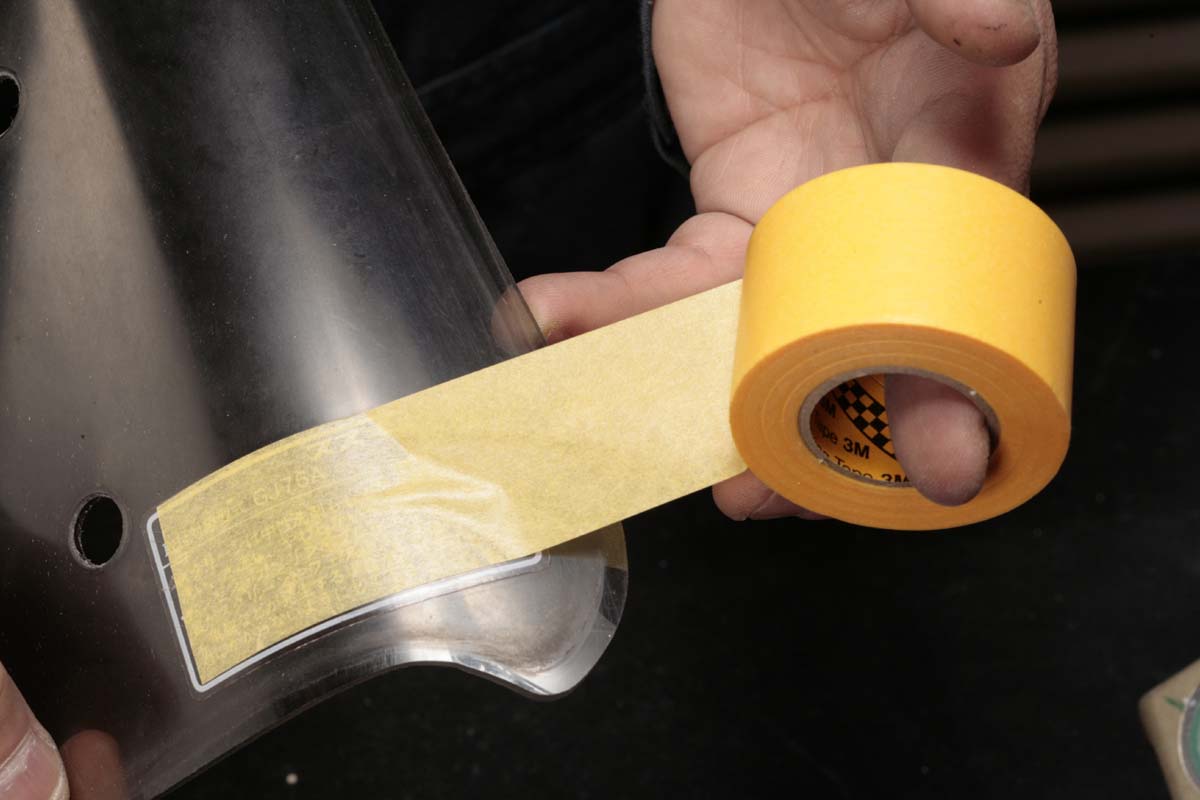

There are wet and dry types of Baflex, but Model Create Maxi, which provided photographic support for this project, prefers to use the wet type. An electric polisher is used for the final finish, and a flannel pad is set. Use masking tape to protect the caution marks that you want to keep without scratches before starting work.

Deciding to go for it, he started with scratch removal.Gradually increasing the grain size number.

This time, after polishing the prominent areas with No. 600 paper due to the depth of the scratches, we worked from No. 800 => No. 1200 => No. 1500 and then finished the entire surface with Baflex Green. It was impressive that he frequently sprayed water with a misting sprayer. Being a smokescreen, and due to surface deterioration, the resin powder scraped off by water polishing was a little yellowish. When wiped off with a tissue, the yellow stain clearly adheres.