Dismantling and Maintenance of Steam Turbine Super Bolts

In the production process of petroleum refining and chemical enterprises, many large units use steam turbines as prime movers to drive the units to run. The components of the steam turbine work at high temperatures and high pressure and super bolts are used for their connection and fastening. These units need to be dismantled and overhauled after a period of operation to eliminate the failures and hidden dangers that occur during the operation of the units. However, super bolts are often encountered in the process of dismantling steam turbines. During disassembly, multiple jack bolts of super bolts cannot be disassembled under the standard torque, and the jack bolts will break when forced demolition.

Therefore, in this article, I will introduce how to solve the problem of complete disassembly and maintenance of super bolts.

1. The structure and principle of super bolt

1.1 Structure of Super Bolt

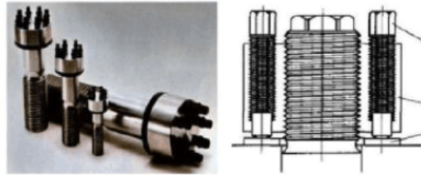

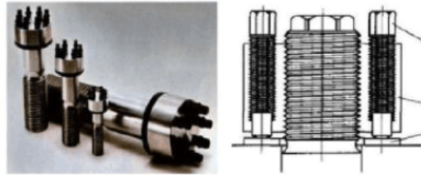

The full name of the super bolt is a multi-stage jackbolt. The super bolt (nut) is composed of a central nut and a circle of concentric multi-stage jackbolts around the central nut, superhard gaskets, and main bolts.

The physical and structural diagram of the super bolt is as follows:

1.2 Fastening principle of super bolts

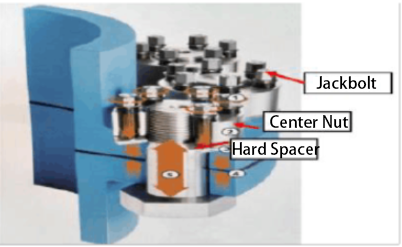

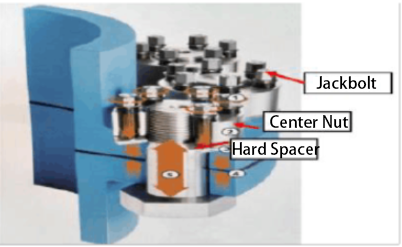

The fastening principle of Super Bolt is shown in the figure on the left. The fastening steps are as follows:

① Install all the jacking bolts on the center nut, and generate a strong jacking force (axial force) by tightening the jacking bolts several times, and make this jacking force act directly on the hard gasket.

② Transfers the load of the jackbolt to the center nut body which has been mounted on the main thread.

③ The jacking force generated by all the fixed thrust bolts is transmitted to the hard gasket, which evenly transmits to the flange and protects the flange surface at the same time.

④ Super nuts and main bolts work together to create a strong clamping force on the flange.

⑤ The jacking force (axial) of the jacking bolt produces the pre-tightening force required by the technology on the main bolt.

2. Super bolt (nut) removal method

In order to disassemble the super bolts intact and efficiently, the steam turbine super bolt disassembly and assembly “342” working method can be used during the maintenance of the unit. This method allows for better disassembly.

2.1 Cleanup

After the steam turbine cover is disassembled, immediately use a wire brush to clean the thread of the center bolt and the jack bolt, clean the dirt between the plug and the hard gasket, and blow it off with compressed air.

2.2 Oil leakage

On the cleaned super bolts at high temperatures, apply the proportioned lubricating oil several times, and use thermal expansion and contraction to make the lubricating oil penetrate into the thread. (The ratio of 48# lubricating oil to kerosene at around 100°C is 40:60. The ratio of 48# lubricating oil to kerosene at around 70°C is 30:70, and the bolt loosener is used at around 40°C).

2.3 Tap

In order to make the lubricating oil penetrate into the thread of the super bolt better, especially the thread of the multi-stage jack screw, and between the plug and the gasket, it is necessary to lightly tap the jack screw with a rubber hammer.

2.4 Find

Try to remove the jackbolts sequentially with a standard torque. If all the ejector bolts cannot be removed, increase the removal torque to 110%-130% of the specified torque, and then try to remove all the ejector bolts in turn. If it is still difficult to disassemble, the ejector bolts are not loose, and then use a special ejector bolt removal wrench to disassemble (the torque that the wrench bears are 3-4 times the specified torque, which should meet the requirements for safe use). The goal is to find and try to remove one of the preloaded jackbolt sets.

2.5 Pull

In order to find and remove a jack bolt and ensure that the jack bolt is not broken or damaged, use a special wrench to disassemble it, and pull it by two people. During the force application process, the force should be applied slowly and evenly.

2.6 Tap

When disassembling by pulling, increase the dismounting force to a certain extent, and the ejector rod bolts are still not loose. At this time, one person hits the special wrench vertically with a 2.5-pound hammer (pay attention to hitting when two people pull it). Loosen the jack bolts by knocking and vibrating, stop knocking when you hear the ‘click’ sound, and remove the jack bolts in the normal way.

2.7 Removing other bolts

Through the three steps of searching, pulling, and tapping, the main purpose is to find a relatively easy and completely disassembled jack bolt among the multi-stage jack bolts. Check and clean the disassembled jack bolts for no damage. After applying a special bolt anti-seize agent, reinstall and tighten with 110% of the specified torque. The purpose of loosening the bolts on both sides is achieved by increasing the jacking force of the jacking rod bolts to reduce the jacking force of the jacking pins on both sides. Disassemble the loose bolts, clean, check, apply anti-seizure agent, reassemble and tighten, repeat the above process until all the ejector bolts are disassembled and reassembled, and then complete the disassembly according to the super bolt disassembly steps.

3. Maintenance of super bolts

Remove all jack bolts from the center nut, clean, and check the threads and jack bolts for bending. If it does not meet the technical requirements, repair or replace it. The head of the jack bolt is ground smoothly, and the contact surface between the hard gasket and the head is ground and repaired to make the surface smooth and flat. Check the deformation of the hard gasket on the platform. When the deformation is not greater than 0.1mm, it can be turned over for use. If the deformation is serious, replace it with a new gasket. Check that the main bolts and center bolts should meet the requirements.

After cleaning all bolts that meet the requirements with the cleaning agent, apply a high-temperature special thread anti-seize agent on the thread surface. Put all the jack bolts back on the center nut, wrap them in a clean white cloth, and store them in a special storage box for later use.

4. In the end

Improper or wrong disassembly method of super bolts will damage and break the ejector rod of super bolts, resulting in the whole set of bolts can only be dismantled forcibly because they cannot be disassembled. Through the above method, the super bolt can be completely disassembled and the loss of the enterprise can be reduced. Now, if you have any questions about super bolts/nuts, welcome to contact us, we will provide free technical support.