Self-drilling screws

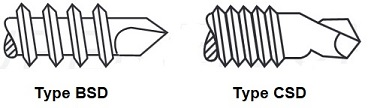

You might notice some of our Self-Drilling Screw spec sheets refer to BSD and CSD styles. Here’s a rundown of what those names mean, and when one or the other might be the appropriate screw for you to use.

BSD Self-Drilling Screws

Most standard self-drilling screws don’t conform to UNC (Unified Coarse Thread) or UNF (Unified Fine Thread) standards.

Screws of this type are classified as BSD. When the diameter of screws of this type are noted, the thread count is not part of the description. These screw diameter descriptions start with a single number (#8 or #12 for example) or a fraction (1/4″ or 5/16″ for example).

The wider spacing between the threads of BSD screws is beneficial for most self-drilling screw applications, as it allows for easier penetration into plywood, soft woods, composition board and some metal materials.

CSD Self-Drilling Screws

Some self-drilling screws do come in Unified Thread Pitch, UNC and UNF.

These screws are identified as CSD screws. They are easy to identify because their diameter is noted with size as well as threads per inch. Screw sizes noted as 10-24, 10-32 or 1/4-20 would fall into the CSD category.

The tighter thread spacing helps reduce friction and required driving torques. Because of this, they are often used with thicker materials.

Relevant problem

How to use self drilling screws?

Use caution when applying excessive force when driving self-drilling screws. Excessive pressure application can lead to point burnout and excessive heat buildup on the screw point. After setting the trigger to the desired revolution per minute and applying just enough pressure to keep the screw steady, insert the screw into the material.