The point-controlled ignition system employs a retro and simple mechanism not found in modern motorcycles. The moment the point contacts open, grounding is interrupted, causing a sudden flow of electricity to the primary coil of the ignition coil (IG coil), which is amplified by the IG coil and transmitted to the plug cord to ignite the spark plug. As such a “key” component of the ignition system, the points play a very important role along with the capacitor connected in parallel. At the same time, they are parts that require regular maintenance.

In this section, we will focus on the maintenance of point models and related issues.

- Dirt on contacts can cause misfires.

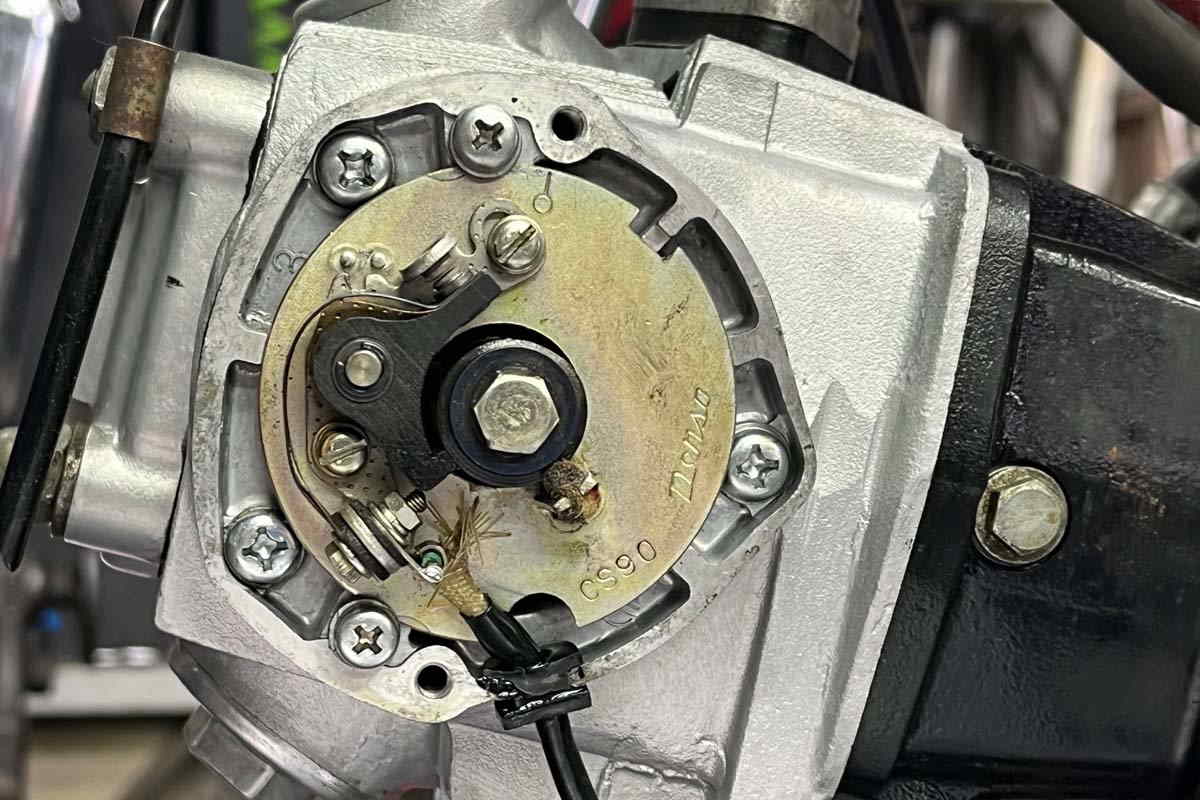

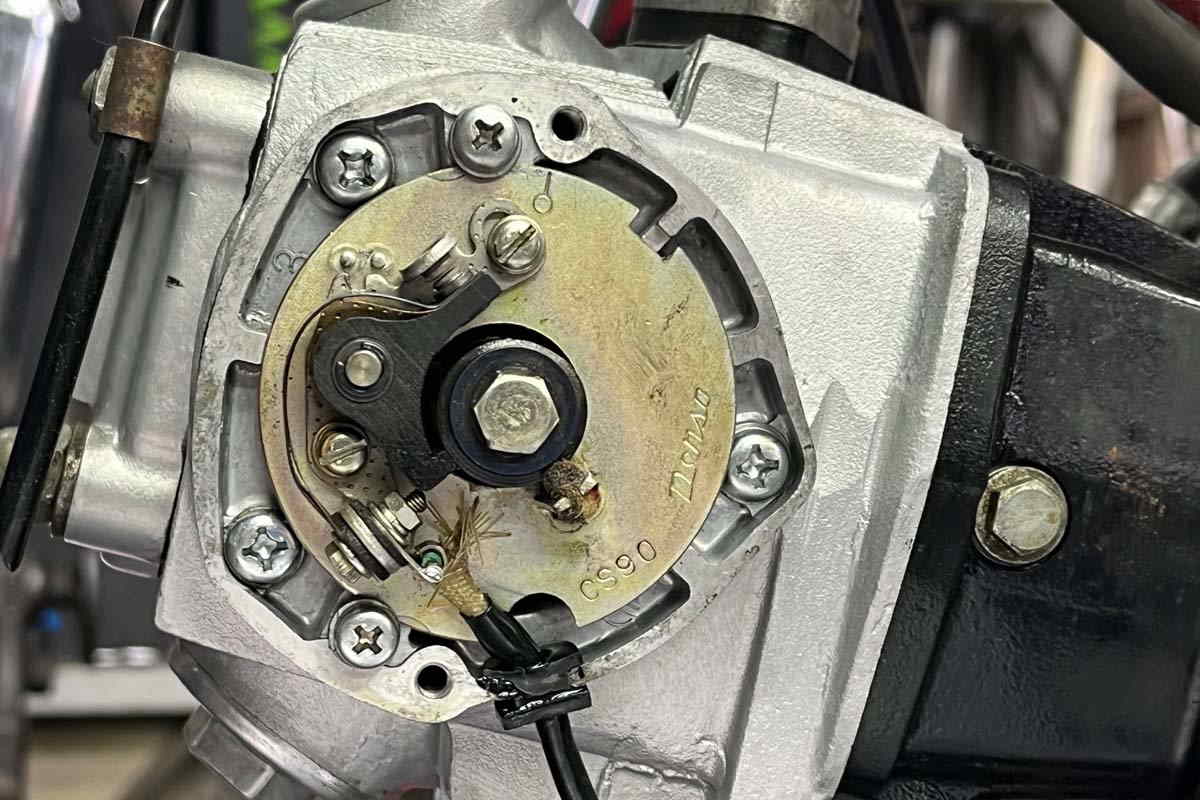

- The timing of opening and closing of point contacts is controlled by the cam mountain.

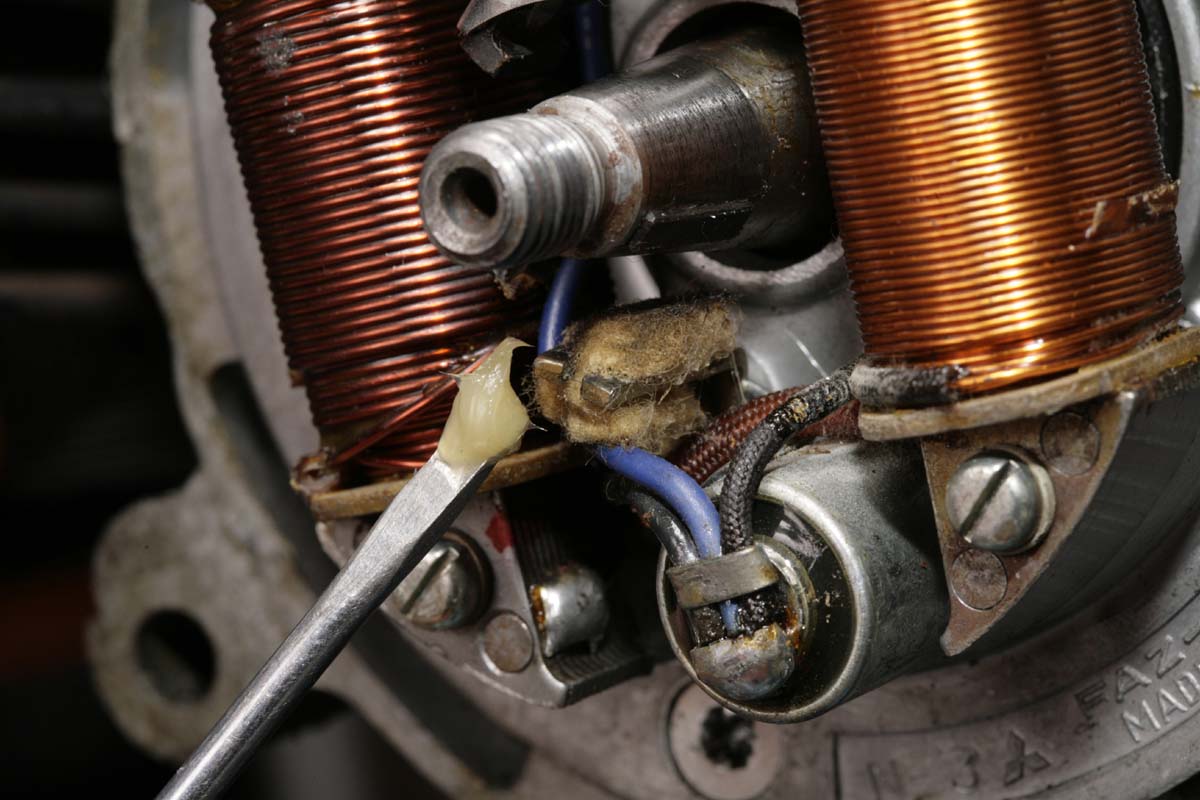

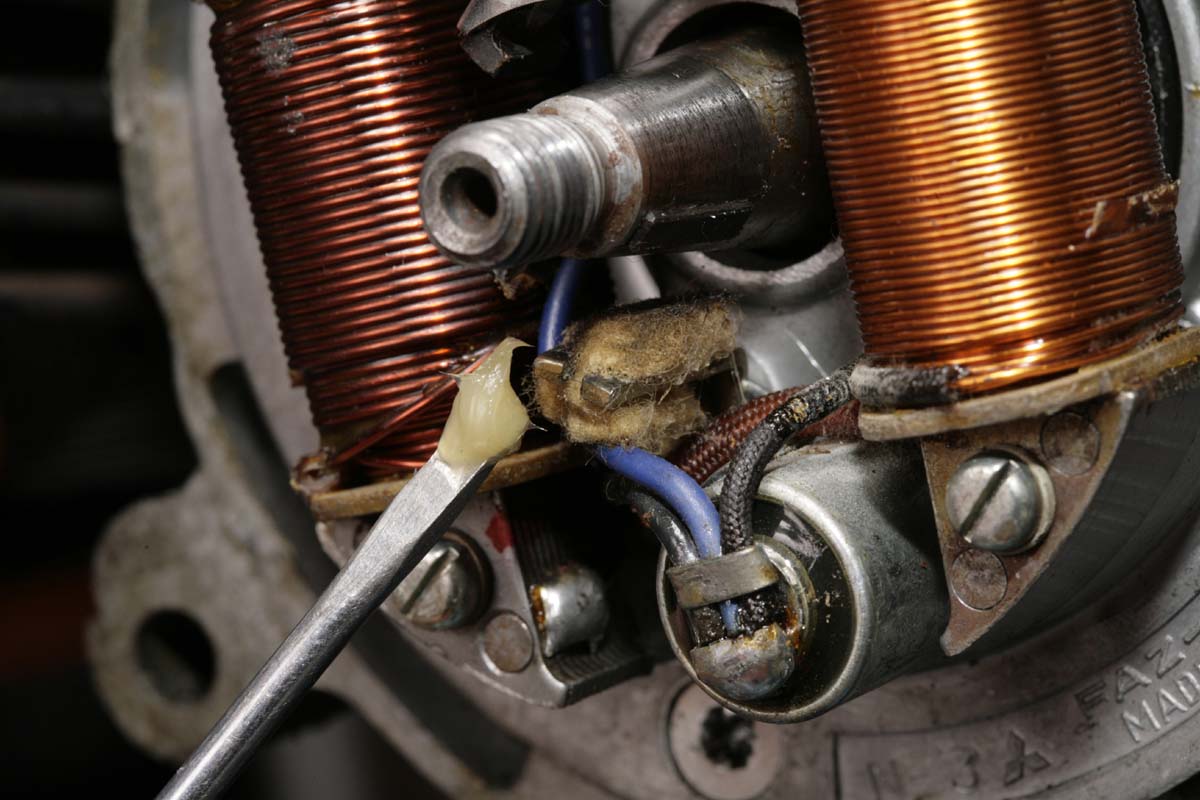

Dirt on contacts can cause misfires.

One of the most important and simple tasks in point maintenance is “cleaning dirt” from the contacts. If the contacts are dirty, even if they are in contact, there is no continuity, so it is as if the points are always open. As a result, the spark plug does not fire because it cannot get a signal to spark. You can clean it with parts cleaner, but it may adversely affect other parts (degreasing the oil), so first cut a piece of copy paper into strips, fold it in half, and insert it between the closed points. The paper will break if the spring tries to pull it out too hard, so use a flat-blade screwdriver or similar tool to lightly lift the point arm and pull the strip of paper out while feeling the tension. This kind of work can remove dirt from the point contacts, but if you cannot remove all of it, it is better to use a parts cleaner or the like.

The timing of opening and closing of point contacts is controlled by the cam mountain.

The points open when a part called the pointed heel, made of Bakelite (reinforced plastic), rides up on the cam crest. In other words, since the pointed heel is sliding against the cam mount, the pointed heel will decrease in size as it is used to some extent, and the ignition timing will become incorrect. That is why it is necessary to periodically check the point adjustment.

Grease is applied to control the point gap reduction, and the oil felt is responsible for holding the grease so that it does not fly out. When practicing point maintenance, the oil felt should be soaked in grease to keep the point cams lubricated at all times. Many 4-stroke engines have an ignition advance function, but the mechanical advance is operated by centrifugal force from engine rotation. The cam mount that interrupts the point contact is an integral part of the spark advance (governor) that performs the ignition advance, so it needs to be regularly inspected, cleaned, and greased.

If the camshaft is not working smoothly, disassemble, clean, and scrub the camshaft, and restore it after greasing it properly.