When turning bolts, nuts, and screws, it is an ironclad rule to use tools appropriate for the size of the screw. However, a little carelessness or messy work, as well as mistakes made by previous workers, can damage the hexagonal corners and cross-holes. We want to do something before decisive damage occurs. In such cases, instead of trying to force the situation, let’s pause and think about how to improve the situation.

- Using the right tool for the size of the bolt or screw is a prerequisite.

- Fate of Plusvis, come-outs are a major cause of crushing crosshairs.

Using the right tool for the size of the bolt or screw is a prerequisite.

Phillips screwdriver tip sizes are distinguished by numbers 1, 2, and 3, and three types are generally used for the cross-holes of screws. If you use a screwdriver with a tip smaller than the cross-hole of the screw, there is a high possibility that the tip will play and damage the cross-hole, so select the size that fits perfectly. Also, if the screwdriver does not stick to the cross-holes due to rust in the cross-holes, it is easy for the screwdriver to come out.

It goes without saying that it is important to always match the size of the screw and tool, such as a 12 mm head bolt with a 12 mm two-face width eyeglass wrench or socket, or a No. 2 screwdriver when turning a screw with a No. 2 cross-hole equivalent. An 11mm spanner will not fit on a bolt with a 2-sided width of 12mm, but a 13mm spanner will, although there is a lot of rattling. Of course, if you notice this rattling, you should use a 12mm tool, which is one size smaller, but if you are careless and try to turn the bolt as it is, it will cause trouble = a hexagonal part will be damaged. Matching the size is one thing, but there is also the risk that the tool you use will damage the apex of the hexagonal part. Spectacle wrenches and sockets that encircle the entire circumference of the hexagonal part make contact with the bolt and nut at six points. On the other hand, wrenches and monkey wrenches, which are placed between two surfaces, make contact at four points, but this is not the case. In fact, they make contact only at two points in both tightening and loosening directions, because there is always a clearance between the two sides of the bolt and nut, which is necessary for attaching and detaching the tool. If the same torque is applied to a 6-point contact eyeglass wrench and a 2-point contact wrench, the wrench will apply 3 times more force to the contact area than the wrench, even if we simply think about it. Although the opening width of a monkey wrench can be adjusted as desired, even if the clearance is tightened, the contact points with the bolt will still be two points when force is applied. It is natural to match the size of the bolt and nut with the size of the tool, but this is the reason why wrenches and monkey keys should be used as little as possible, except in places where eyeglass wrenches and sockets cannot physically fit.

Fate of Plusvis, come-outs are a major cause of crushing crosshairs.

The entrance to the cross-hole will twist when it is about to come out, so correct it as soon as possible when you notice it. If you try to turn it forcibly as it is, the cross-hole will become twisted and you will not be able to do anything about it.

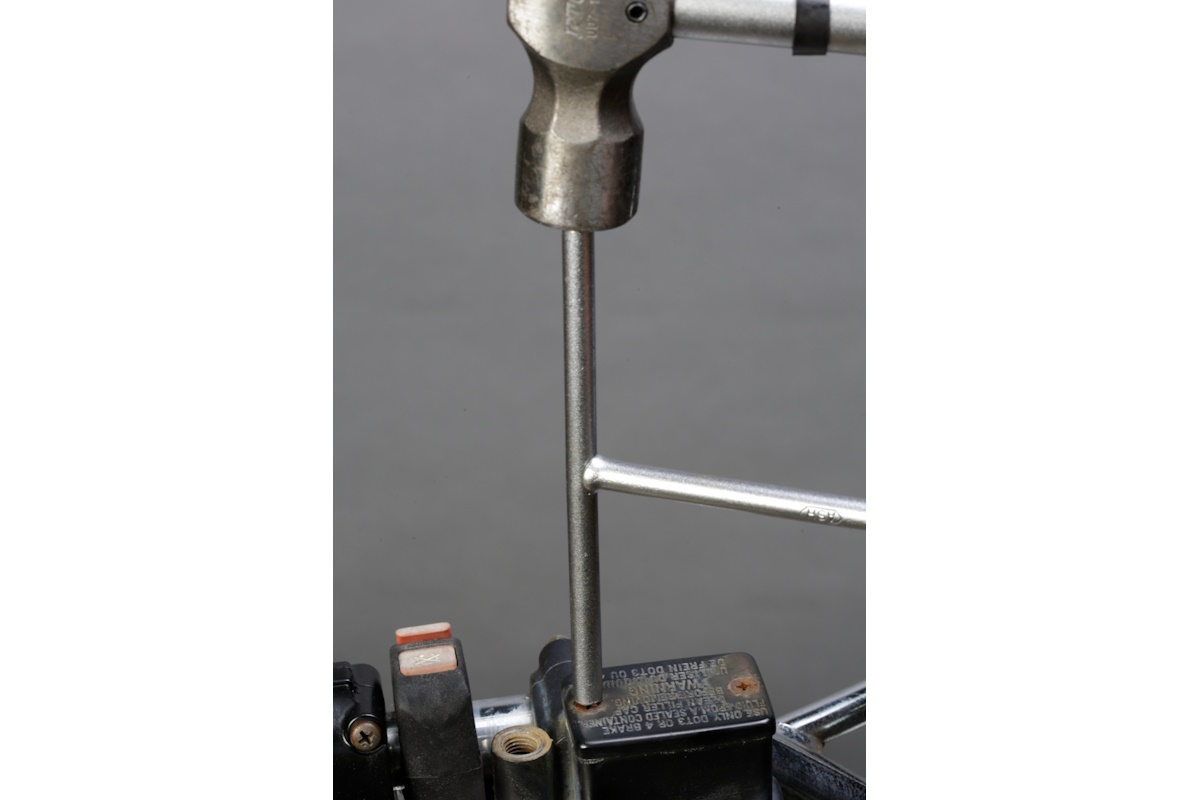

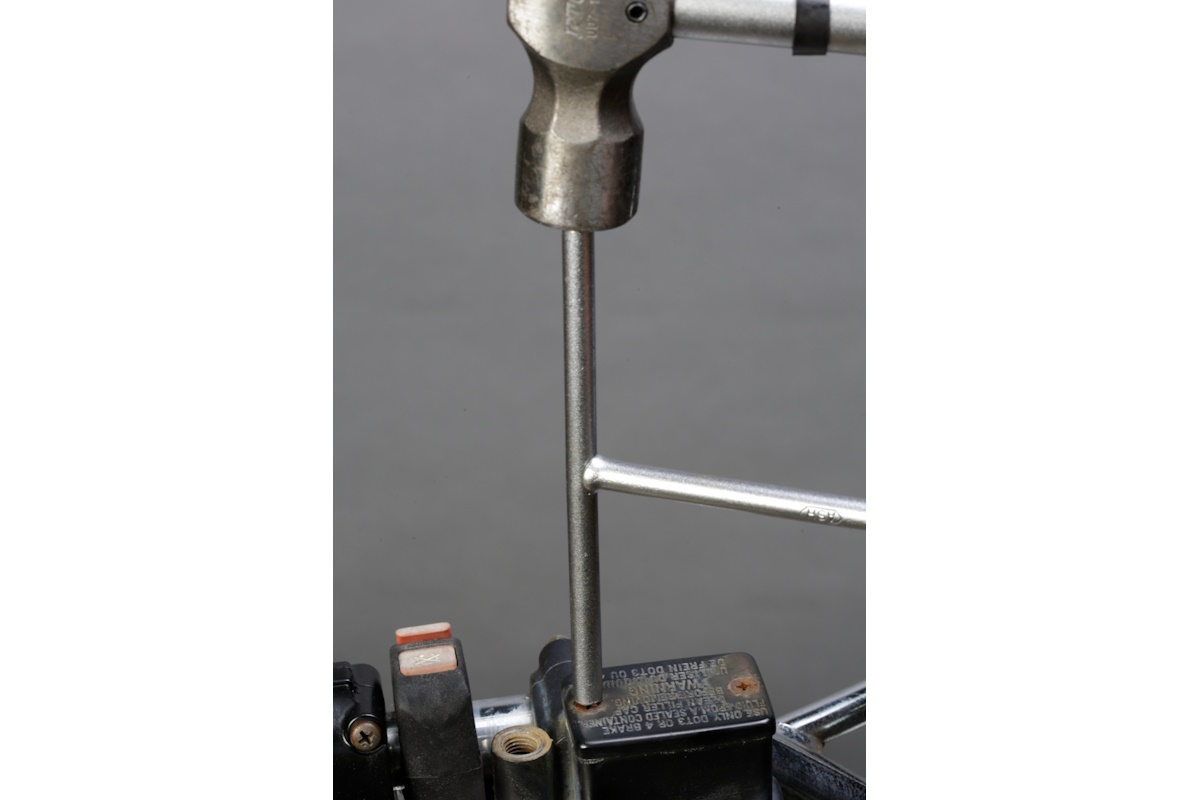

In some cases, a flat punch or T-handle handle can be used to temporarily repair a broken cross-hole by hitting the head of the screw with a hammer. However, the repaired cross-hole is brittle, so there is a high possibility that the screwdriver will be tampered with again when trying to turn it.

In such cases, use a shock driver that exerts both striking and rotating force to loosen with a single blow. Even though the screwdriver is turned by hand while pushing, the rise in rotational force is gradual, which can easily induce a come-out. In contrast, a shock driver or electric impact driver has a rapid rise in torque, making it effective against screws that are stuck.

If the cross-holes are crushed and the screwdriver will not catch, it may begin to turn by cutting a groove by biting into the cross-holes and striking in the loosening direction. Since the screwdriver will not turn if the striking force is weak, the key to success is to strike the taganets firmly.

The two most common causes of damage to cross-holes in Phillips screws are cam-out and clogged cross-holes. The cross-holes, which taper toward the tip, are characterized by good screwdriver accessibility, but when rotary torque is applied, the tip of the screwdriver bit will try to lift out of the cross-holes. This phenomenon is called come-out. To prevent this, it is an ironclad rule that when using a screwdriver, it should be turned while pressing down on the screw. However, if the pressing force is too weak when turning a sticking screw with high torque, the cross-hole will collapse. If the screwdriver is still forced to turn, the tip of the screwdriver will act like a drill and shave the cross-hole, making it impossible to apply the tool at all. To avoid this, it is important to press the screwdriver firmly against the screw.

Each tool manufacturer has its own ingenious measures to prevent the screwdriver from camming out. However, due to the fundamental structure of the screw and screwdriver, it is not possible to prevent the screw from coming out except by the act of pressing down.

Therefore, we recommend using a shock driver (impact driver) as soon as possible for screws that have stuck. A shock driver is often thought of as a last resort, but a hammer blow is much more effective than a weighted grip.

Electric impact drivers are also effective in that they apply a powerful rotary torque while pressing down on the tool. Since come out often occurs when the tip of the screwdriver gradually lifts out of the cross-hole of the screw, an electric tool that can apply maximum torque all at once has the advantage of focusing only on pushing the bit onto the bit.

If the cross-hole is still about to be crushed, it is important to take care of the problem while it is as minor as possible. Specifically, correct the cross-hole that is about to collapse by tapping it with a flat punch or the handle of a T-shaped wrench, and then apply torque all at once with a shock driver or electric impact driver to increase the likelihood of loosening the stuck screw.

What should also be noted before the come-out is the dirt in the cross-holes. If the screw is new, the screwdriver will penetrate deep into the cross-holes, but if the screwdriver is clogged with dirt and rust, the tip of the screwdriver will not stick and will float without transmitting enough pressing force or rotational torque. When there is a problem with the bike, it is natural to want to reach the affected area as quickly as possible, but it is also important to allow enough time to wash the bike first so that you can use the tool if it is too dirty.